A major breakthrough in EV battery technology is here, and it could change everything.

Stellantis, the global auto group behind Jeep, Dodge, Chrysler, and Peugeot, has successfully validated solid-state battery cells from U.S. battery startup Factorial Energy. This validation marks one of the most important moments in next-generation battery tech in years—and signals that the solid-state era may finally be within reach.

The milestone? Stellantis verified Factorial’s 77Ah solid-state lithium-metal battery cells for use in real-world vehicles. With this, we’re no longer talking about theoretical improvements. We’re talking about batteries with more energy, faster charging, and safer operation than what’s currently in your EV—or any EV on the road today.

Let’s dive into what this means, how soon it’s coming, and why every automaker—and EV buyer—should be paying attention.

What Are Solid-State Batteries?

Current EVs use liquid-based lithium-ion batteries. They’re heavy, complex, temperature-sensitive, and prone to degradation. Solid-state batteries replace the liquid electrolyte with a solid material, unlocking multiple advantages.

Key Benefits:

- Higher Energy Density

Store more energy in the same physical space, giving EVs longer range. - Faster Charging

Stellantis reports the battery can charge from 15% to 90% in just 18 minutes at room temperature. That’s faster than most fast-charging EVs today. - Improved Safety

Without flammable liquids, the risk of thermal runaway, leaks, or fires is dramatically reduced. - Longer Life

Solid-state batteries degrade slower, keeping performance high even after hundreds of charge cycles.

The Stellantis–Factorial Energy Partnership

This isn’t a new relationship. Stellantis invested €75 million (approx. $85 million) in Factorial Energy back in 2021, targeting solid-state development under its Dare Forward 2030 strategy. The goal: lead the industry in EV technology across its 14 brands.

In April 2025, Stellantis and Factorial hit a new milestone—the successful automotive-grade validation of a 77Ah solid-state cell. This is not a lab test. This is a step toward installing these batteries in real production vehicles.

The cell demonstrated:

- 375 Wh/kg energy density

- Over 600 charge cycles

- Stability and performance suitable for use in passenger vehicles

This puts Factorial’s proprietary FEST (Factorial Electrolyte System Technology) at the front of the solid-state race.

What’s Coming Next? A Demo Fleet by 2026

Validation means the tech works. Now, Stellantis is preparing to install these batteries into a real demonstration fleet by 2026.

The first vehicles expected to receive solid-state batteries are:

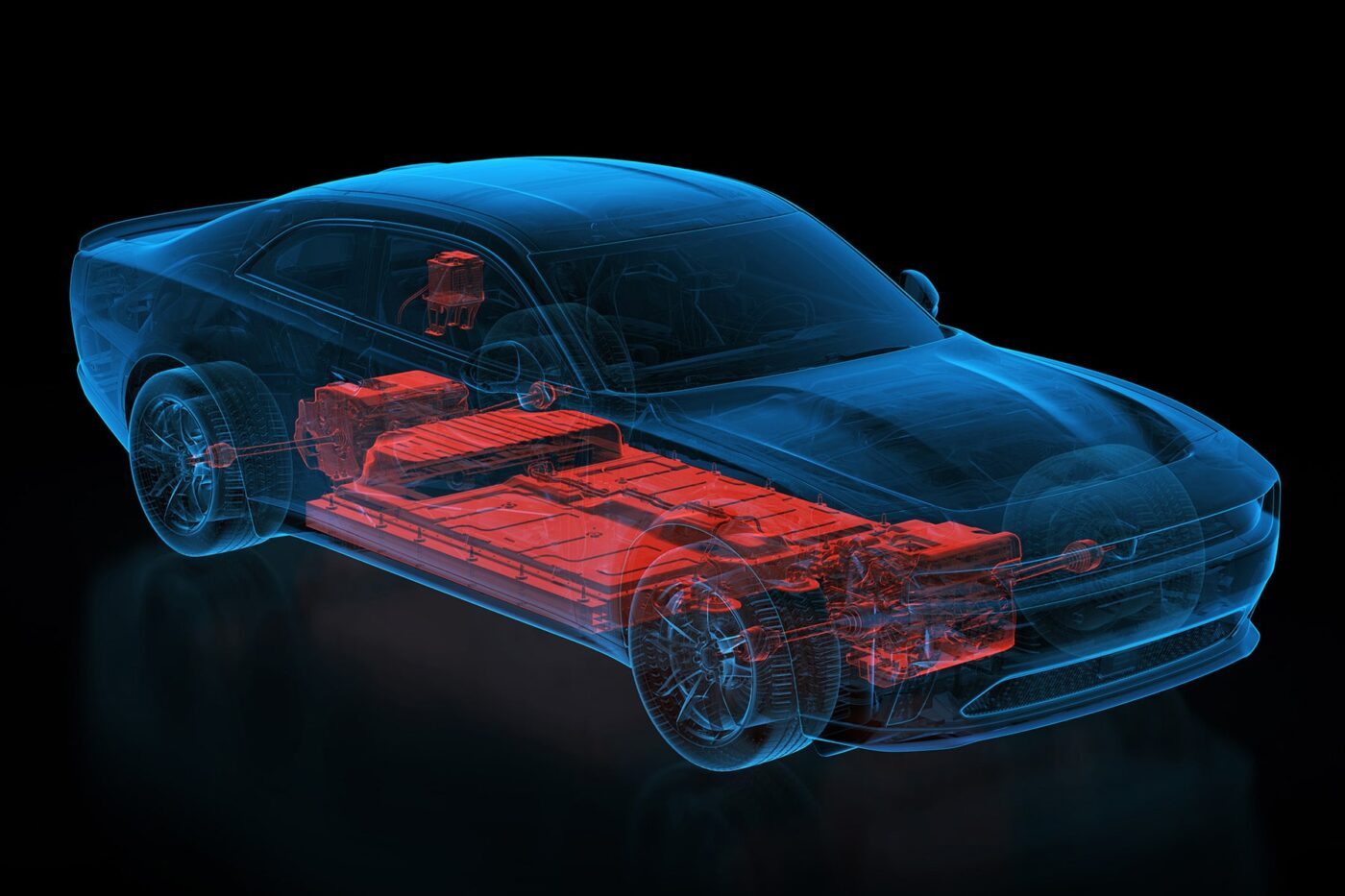

- A new Dodge Charger Daytona EV

- Future platforms under STLA Large, which underpins EVs for Dodge, Chrysler, Jeep, and Alfa Romeo

This puts Stellantis ahead of Toyota, Hyundai, and even GM in terms of real-world solid-state rollout timelines.

Once the demo fleet hits the road, Stellantis will gather performance, durability, and charging data from vehicles in actual consumer conditions—not test tracks or labs.

What This Means for EV Buyers

This news could radically shift the EV landscape in the next 2 to 4 years.

Here’s why it matters:

- More Range Without Bigger Batteries

Higher energy density means future electric SUVs and sedans can go 400 to 500 miles on a single charge—without larger battery packs. - Ultra-Fast Charging

15 to 90% in under 20 minutes would make EV charging as fast as a gas station stop. - Lower Battery Costs Long-Term

Solid-state batteries are more efficient and could use fewer rare materials, helping reduce EV prices as production scales. - Increased Consumer Confidence

Better safety and durability will appeal to buyers still nervous about EV reliability or battery longevity.

Industry Impact: Who’s Competing in the Solid-State Space?

Stellantis is now among a short list of automakers actively validating large-format solid-state cells for road use.

| Automaker | Solid-State Partner | Status (as of 2025) |

| Stellantis | Factorial Energy | 77Ah cell validated; demo fleet in 2026 |

| Toyota | In-house + Panasonic | Limited lab testing; 2027–2028 timeline |

| BMW & Ford | Solid Power | Pilot lines; no vehicle integration yet |

| Hyundai-Kia | Solid Power, SES AI | Joint development; 2026–2027 demos |

| Nissan | In-house | Prototype pack under lab conditions |

Most of these companies are still working at the lab or pilot stage. Stellantis is the first to move toward real-world fleet use, placing it well ahead of schedule.

What Is FEST Technology?

Factorial’s FEST system isn’t just another solid-state recipe. It blends a lithium-metal anode with a proprietary solid-state electrolyte, achieving:

- Higher performance without sacrificing stability

- Scalable manufacturing using existing lithium-ion infrastructure

- Compatibility with conventional EV pack designs

This makes it cheaper and faster to integrate than some other solid-state approaches. FEST is also patent-protected, giving Factorial and Stellantis a unique competitive edge.

The Bigger Picture: Stellantis Aims to Lead EV Tech by 2030

This battery validation fits into a much broader roadmap.

By 2030, Stellantis plans to:

- Launch 75 battery-electric vehicles (BEVs)

- Reach 100% EV sales in Europe and 50% in North America

- Deploy four global EV platforms (STLA Small, Medium, Large, Frame)

- Offer solid-state batteries with up to 500 miles of range

Solid-state is a cornerstone of this strategy—and now, it’s becoming a reality.

Final Thoughts: The Solid-State Future Is Getting Real

For years, solid-state batteries were seen as the holy grail of EVs—always “five years away.” Now, Stellantis and Factorial Energy are showing that timeline might have been too conservative.

This isn’t just good news for Stellantis brands like Dodge, Jeep, and Chrysler. It’s good news for everyone who wants an EV that charges faster, drives farther, and lasts longer.

By 2026, the first cars with these advanced batteries will be on the road. And once they are, expect every other automaker to race to catch up.